DEDSmart® Advanced Metal Manufacturing Solutions

FormAlloy Technologies, Inc. is a leading provider of Directed Energy Deposition (DED) systems and services. Its DEDSmart® metallic tech delivers precise metal powder and wire deposition for additive manufacturing, joining, and repair applications, enabling greater flexibility and efficiency across advanced manufacturing industries.

FormAlloy Technologies provides DED systems and services, delivering precise metal deposition for additive manufacturing, joining, and repair through its DEDSmart® Metallic Tech.

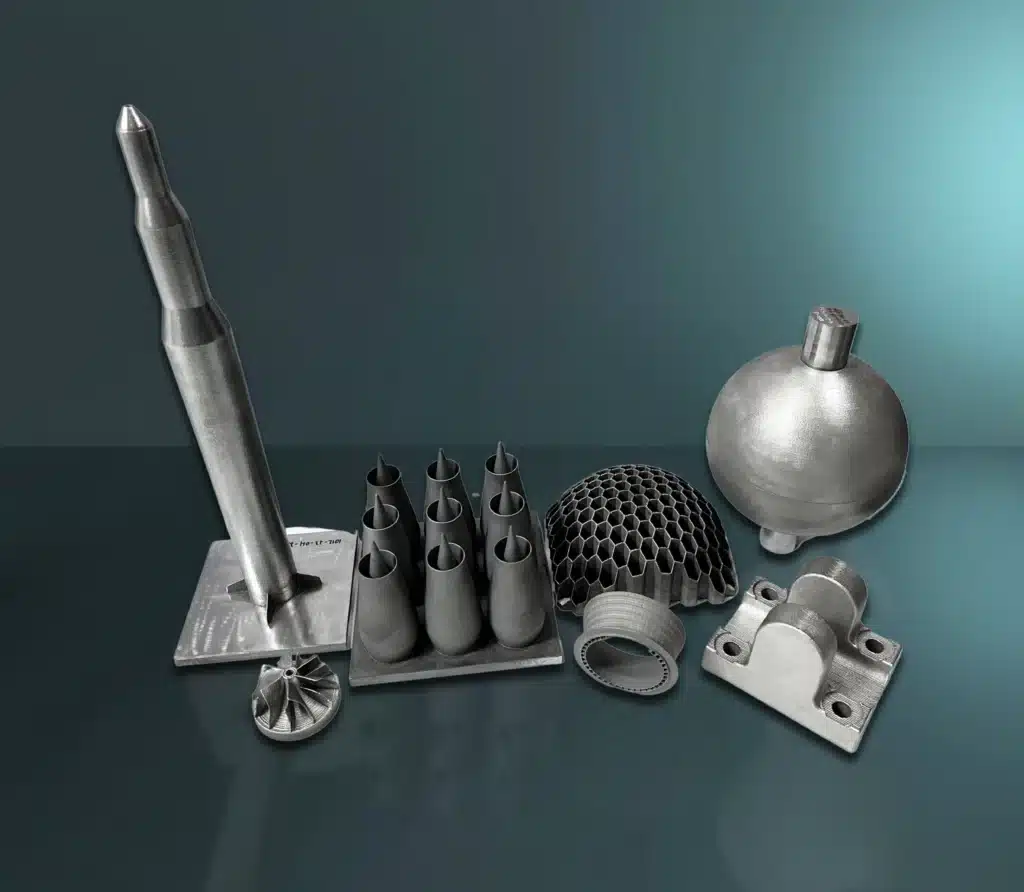

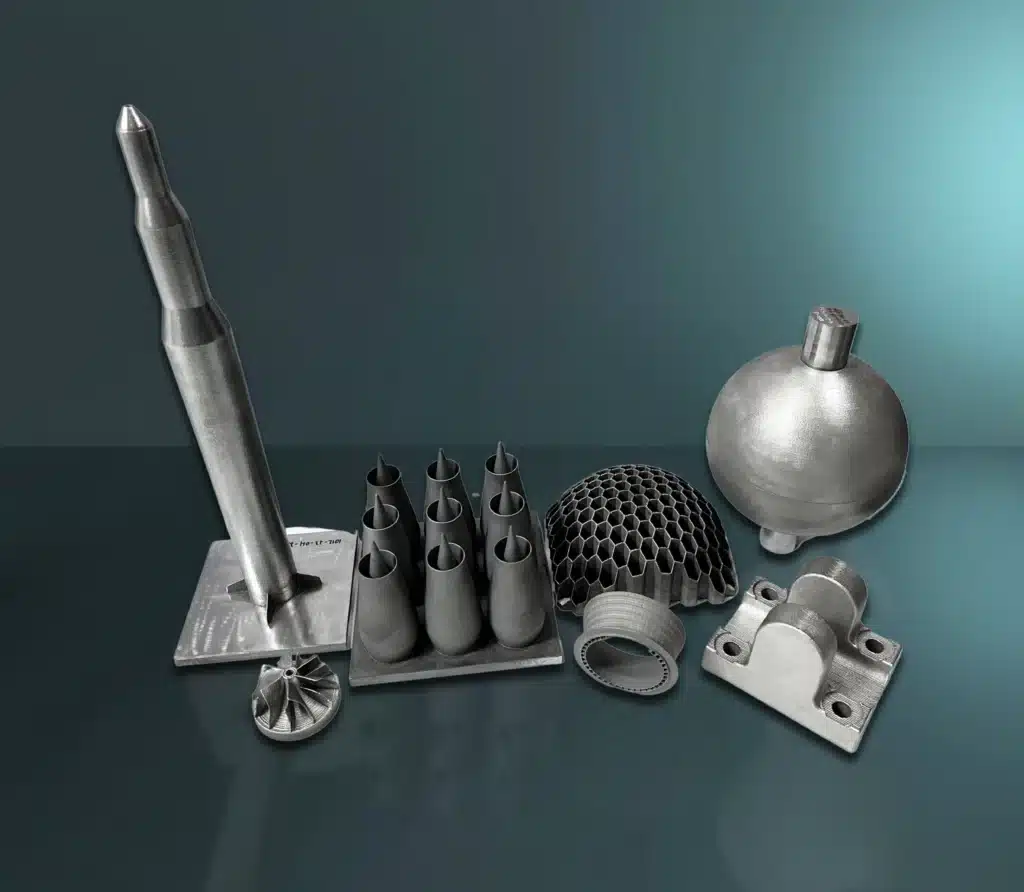

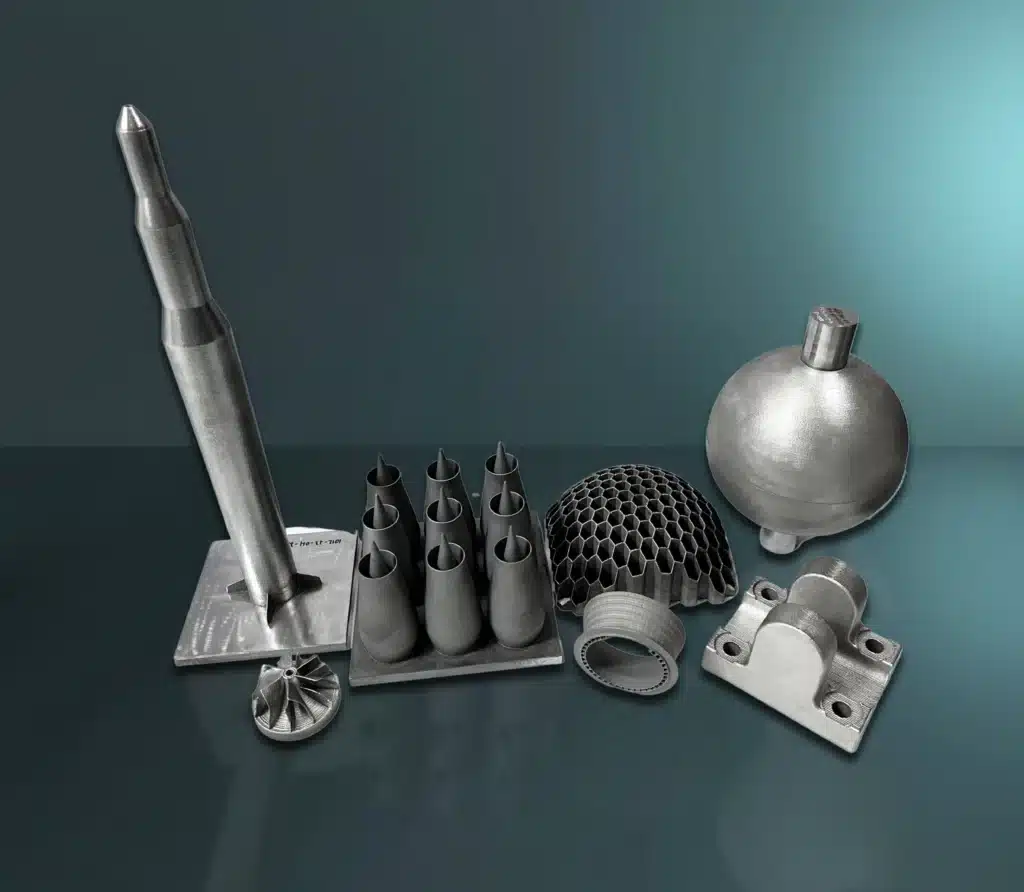

FormAlloy DEDSmart Technology enables unique designs, producing high-quality, repeatable parts 2-100x faster with superior monitoring. It enhances products with multi-material features, wear-resistant coatings, and improved mechanical properties. It also repairs components with fully dense, metallurgically bonded layers, minimizing post-processing.

FormAlloy DEDSmart Technology creates precise, repeatable parts faster, enhances products with multi-material features, and repairs components with metallurgically bonded layers.

FORM

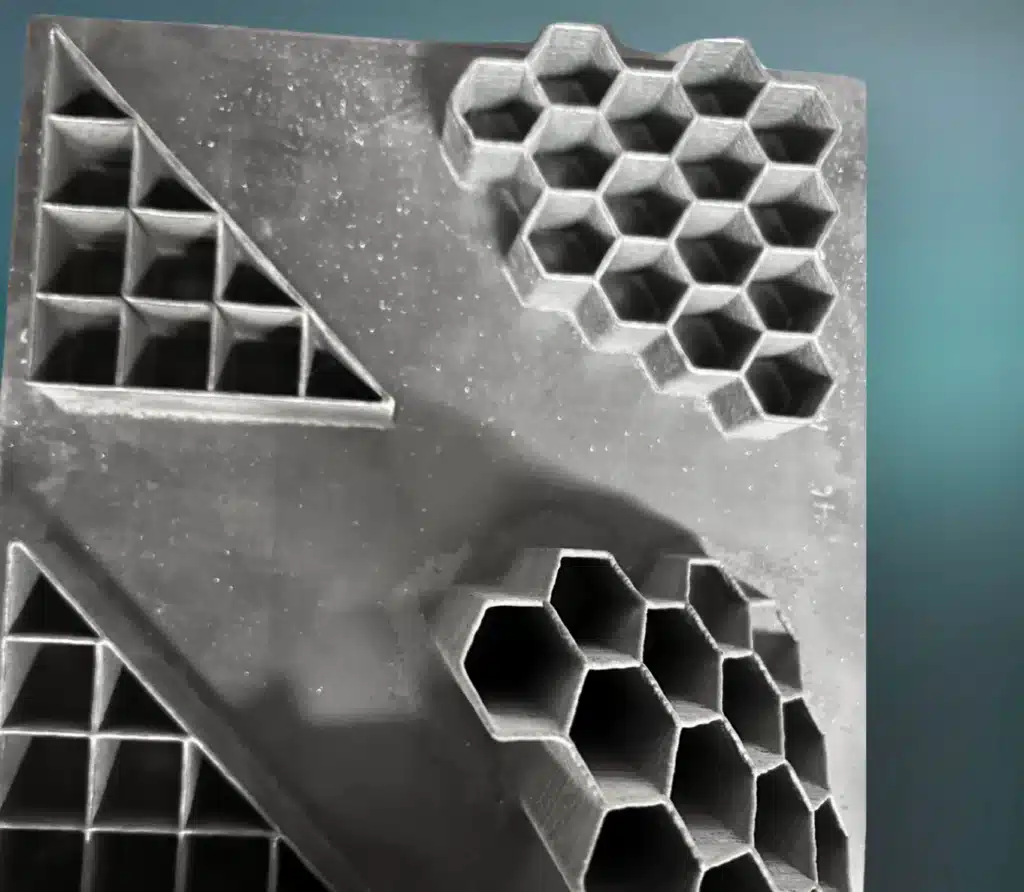

Our DEDSmart® Directed Energy Deposition (DED) process can provide design features that can’t be achieved with conventional metal additive manufacturing solutions; creating high quality, repeatable parts 2-100x faster than other methods with exceptional in-process monitoring and control for quality and repeatability.

Our DEDSmart® DED process creates high-quality, repeatable parts 2-100x faster than conventional methods with exceptional in-process monitoring and control.

Multi-Material Components

IN718

IN625

Copper Component

Laser Cladding Technology

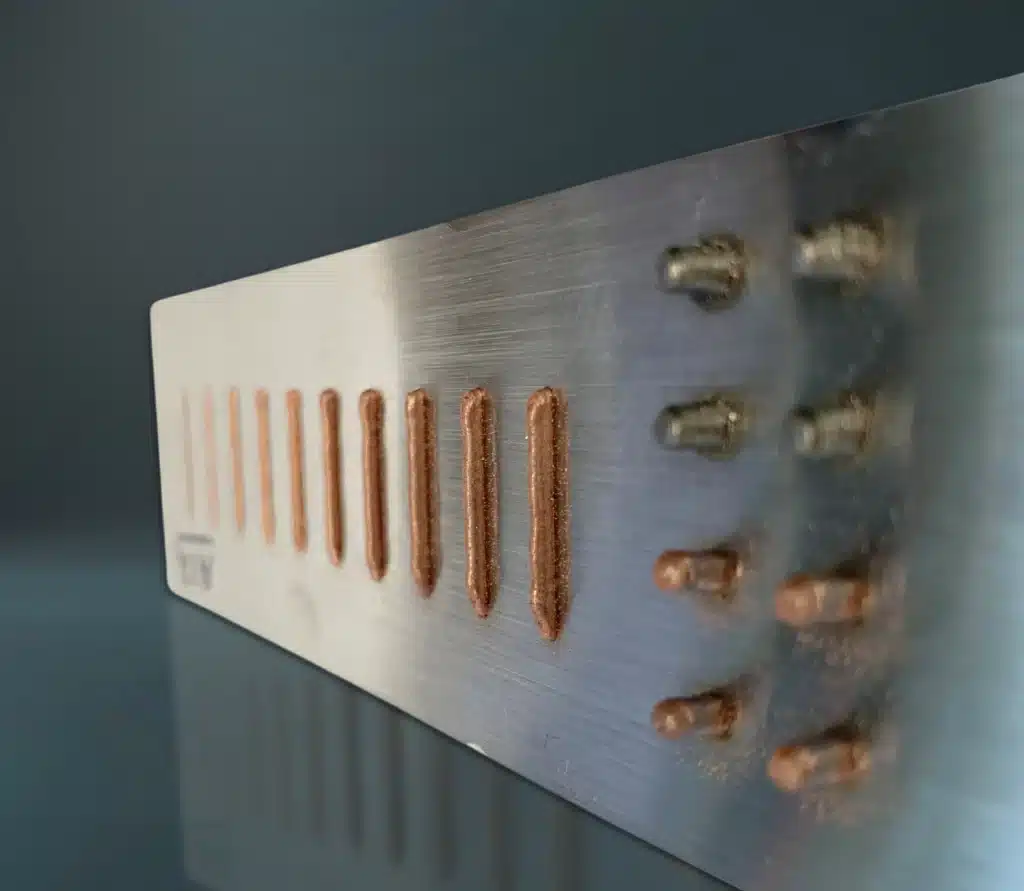

FormAlloy’s DEDSmart® technology delivers precision, speed, and reliability. Real-time monitoring ensures quality when processing IN718, IN625, Stellite 6, and Copper + IN625 Clad for aerospace, industrial, and high-performance applications. Optimize designs, enhance efficiency, and achieve next-generation performance.

FormAlloy’s DEDSmart® technology ensures precision, speed, and reliability with real-time monitoring for consistent quality and next-generation performance.

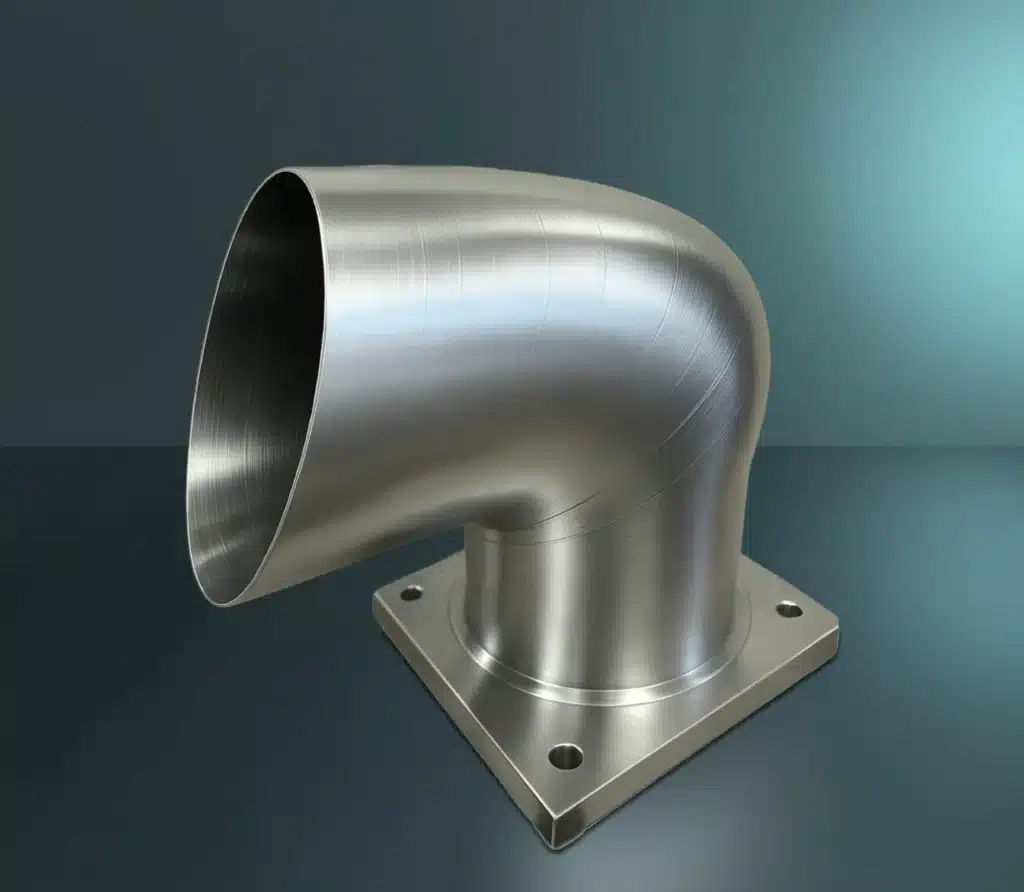

ENHANCE

With the capability to add features and multiple materials, FormAlloy systems improve legacy and new products, improving mechanical properties to higher temperature capabilities. Our unique cladding capability can also be used to create wear and corrosion-resistant coatings that are fully dense and bonded metallurgically.

FormAlloy systems enhance products with multi-material features, improving strength, temperature resistance, and corrosion protection through metallurgically bonded coatings.

Advanced Metal Manufacturing Solutions

IN718

Additive Manufactured Door Handle

FormAlloy’s DEDSmart® technology enhances performance with advanced metal manufacturing solutions capabilities. Strengthen components, improve durability, and extend service life with metallurgically bonded coatings and multi-material solutions. Achieve superior wear, corrosion, and heat resistance for demanding applications.

FormAlloy’s DEDSmart® technology strengthens components, improves durability, and enhances wear, corrosion, and heat resistance with metallurgically bonded coatings and multi-material solutions.

REPAIR

FormAlloy’s REPAIR technology can be used to rebuild damaged or worn areas of valuable machine components, dies or molds. Our DEDSmart® Directed Energy Deposition (DED) process produces fully dense, metallurgically bonded features to the damaged part, with layer thickness from microns and up, thus enabling a variety of repair applications that require minimal post-processing.

FormAlloy’s DEDSmart® technology restores worn components with metallurgically bonded layers, enabling precise, durable repairs with minimal post-processing.

Repair Process

IN718

FormAlloy’s DEDSmart® technology restores damaged components with precision and strength. Achieve durable, metallurgically bonded repairs with minimal post-processing. Extend equipment life, reduce downtime, and enhance performance for critical applications.

Extend equipment life with FormAlloy’s precision repairs. Achieve durable, metallurgically bonded restoration with minimal downtime for critical applications.